The Three Parties Jointly Established a Special Equipment Graphene Zinc Long-Term Anti-Corrosion Demonstration Site to Jointly Promote the Application Of New Materials and New Technologies

Release time:

May 13,2024

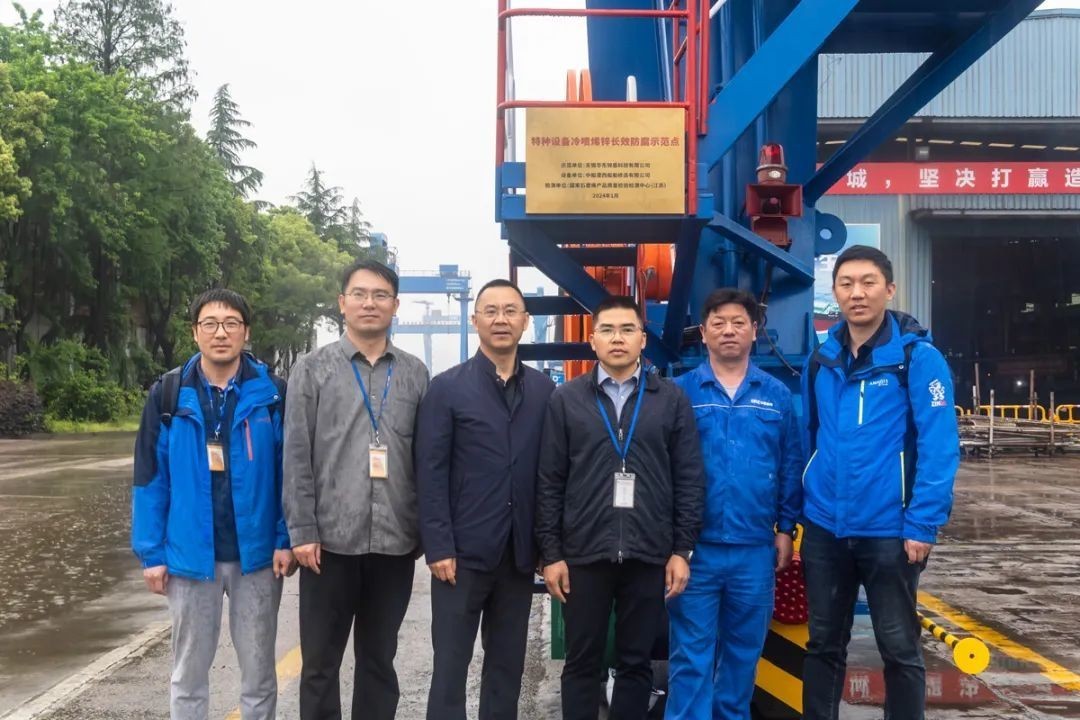

At the beginning of 2024, Wuxi Huadong Zindn Technology Co., Ltd. and CSSC Chengxi Shipbuilding Co., Ltd. jointly established a special equipment Zindn graphene zinc long-term anti-corrosion demonstration site with the National Graphene Product Quality Inspection and Testing Center (Jiangsu).

Founded by three parties

Special equipment graphene zinc long-term anti-corrosion demonstration site

——Jointly promote the application of new materials and new technologies—

Demonstration unit: Wuxi Huadong Zindn Technology Co., Ltd.

Equipment manufacturer: CSSC Chengxi Shipbuilding Co., Ltd.

Testing unit: National Graphene Product Quality Inspection and Testing Center (Jiangsu)

At the beginning of 2024, Wuxi Huadong Zindn Technology Co., Ltd. and CSSC Chengxi Shipbuilding Co., Ltd. jointly established a special equipment Zindn graphene zinc long-term anti-corrosion demonstration site with the National Graphene Product Quality Inspection and Testing Center (Jiangsu). This is an important industry cooperation project. It will promote the widespread application of graphene zinc technology and the innovative development of the anti-corrosion coating industry, and also provide strong guarantees for the safe operation of special equipment.

Wuxi Huadong Zindn Technology Co., Ltd. focuses on the research and development, production, sales, and construction of integrated services in the field of industrial corrosion protection to provide long-term, green, and reliable steel protection. Zindn Technology, together with the Suzhou Institute of Nanotechnology of the Chinese Academy of Sciences and China Chemical Donghua Engineering, jointly developed the PUS pure thin graphene technology, which is the core of the long-term corrosion protection of new coatings. In 2023, Zindn, as the first editor-in-chief of the industry, released the bridge industry graphene zinc application standard T/CHTS 10105-2023 "Technical Guidelines for Graphene Zinc Protective Coating of Highway Bridge Steel Structures".

The National Graphene Product Quality Supervision and Inspection Center is located in Huishan Economic Development Zone, Wuxi City, Jiangsu Province. It was approved by the General Administration of Quality Supervision, Inspection and Quarantine on March 28, 2016. It is built on the basis of the Jiangsu Special Equipment Safety Supervision and Inspection Institute. It is the first national-level graphene inspection and testing technology service platform in China that has been built with administrative approval and can provide third-party inspection and testing services. The construction of the center's inspection and testing laboratory began in 2014. It now has nearly 100 million yuan of high-precision and advanced equipment for inspection and testing of metal materials, polymer materials, nanomaterials, and graphene-like materials, and has high-level graphene professional inspection and testing engineers. In December 2015, the 25 graphene-like inspection and testing projects in four categories applied by the center passed the CNAS on-site review.

CSSC Chengxi Shipbuilding Co., Ltd. is a member unit of China State Shipbuilding Corporation and a wholly-owned subsidiary of China State Shipbuilding Corporation, a listed company. Its main businesses are divided into four business sectors: defense industry, marine industry, application industry, and marine service industry. The company's headquarters are located in Jiangyin, the geometric center of the Suzhou-Wuxi-Changzhou Economic Zone, an important transportation hub in the lower reaches of the Yangtze River, and is only 80 nautical miles away from the Yangtze River estuary. The headquarters' production area covers an area of 770,000 square meters, with a quayside outfitting wharf of 1,557 meters, and has one 80,000-ton, one 100,000-ton, and 170,000-ton floating docks, one 80,000-ton slipway, and one inner harbor wharf, as well as seven 10,000-ton deep-water wharf berths.

Demonstration point anti-corrosion plan

120μm graphene zinc + 80μm acrylic polyurethane

Comparison of details before and after repair

The long-term anti-corrosion demonstration site for graphene zinc on special equipment established by the tripartite cooperation aims to apply and promote graphene zinc technology more widely and promote the innovative development of the anti-corrosion coating industry. The tripartite cooperation will form a close industrial chain cooperation relationship and jointly promote the application of new materials and new technologies.