Zindn Cold Galvanizing Compound Anti-Corrosion | The World's First Five-Tower One Million Unit Project Record

Release time:

Mar 12,2025

The Huaneng Zhengning 2×1000 MW peak-shaving coal-fired power project is located in Zhengning County, Qingyang City, Gansu Province.

The World's First "Five Towers in One"

Million units]

—— Successfully passed the 168-hour trial run——

●●●

PART.01

Project Overview

The Huaneng Zhengning 2×1000 MW peak-shaving coal-fired power project is located in Zhengning County, Qingyang City, Gansu Province. It is an important part of Huaneng Longdong Multi-energy Complementary Comprehensive Energy Base, a supporting peak-shaving project for the "Longdong Power into Shandong" project, and one of the major projects determined to be implemented in the National "14th Five-Year Plan" Outline and the Yellow River Basin Ecological Protection and High-quality Development Plan.

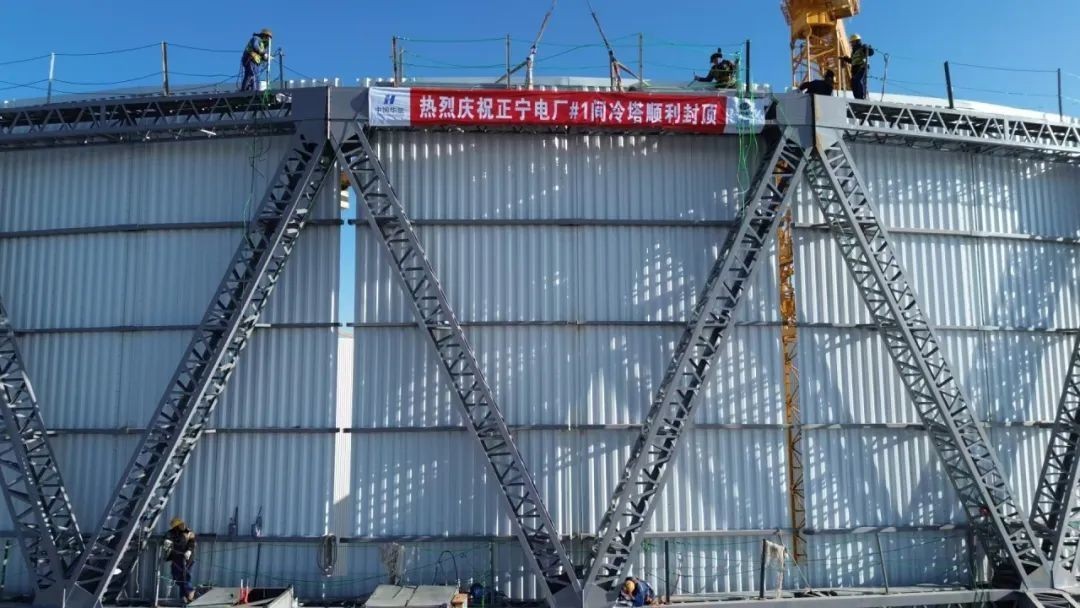

A major highlight of the project is the first use of a "five-tower-in-one" steel structure indirect air cooling system that integrates the main system, auxiliary system, desulfurization absorption tower, CCUS system original flue, and chimney.

the steel structure intercooler tower is 190.5 meters. The radiators are arranged vertically around the outside of the intercooler tower. The main machine radiator and auxiliary machine radiator are arranged in layers and jointly cooled. The auxiliary machine radiator is arranged below the main machine radiator. It has the significant advantages of low construction investment, small footprint, short construction period, low safety risk, high residual value recovery, good seismic performance, and being green and pollution-free.

PART.02

Steel structure anti-corrosion

The steel structure's anti-corrosion of this project consists of cold galvanizing compound and polyurethane topcoat. The cold galvanizing compound at the bottom layer provides a solid basic protective layer that can effectively resist corrosion factors; the polyurethane topcoat on the surface not only provides additional protection but also gives the surface excellent weather resistance and aesthetics.

This innovative composite protection system can increase the protection period by more than 3 times compared to traditional processes. Its environmental performance is excellent, the pollution to the environment is reduced during the construction process, and the construction is convenient and efficient, which is particularly suitable for large industrial projects. Whether it is salt spray resistance, humidity and heat resistance, or UV resistance, Zinc Shield technology performs well, setting a new benchmark for the full life cycle management of ultra-large power generation facilities. Choosing our solution means choosing reliability, durability, and environmental protection.

PART.03

Zindn Cold Galvanizing Compound

Cathodic protection

Sacrificial anode is one of the important means of cathodic protection. The sacrificial anode method is used to achieve cathodic protection for steel components. Zinc is a commonly used anode material for the sacrificial anode method. The standard electrode potential of zinc is -0.76V, which is more active than iron's -0.44V. When zinc is coated on a steel substrate, zinc will be preferentially corroded to release electrons to flow to the steel, thereby protecting the steel substrate from corrosion. Zindn cold galvanizing compound uses ultra-pure ultra-fine zinc powder with a special conductive fusion agent, which has better cathodic protection performance.

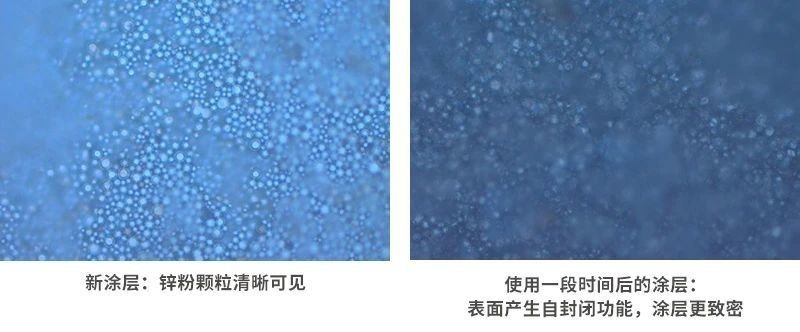

Shielding protection

The zinc layer exposed to the environment will gradually react with water, air, and other corrosion products in the environment over time to generate stable basic zinc carbonate (commonly known as white rust). This corrosion product fills the gaps between zinc powders, making the cold galvanizing compound coating more compact, further blocking and shielding the erosion of corrosive media. The cold galvanizing compound coating has a self-sealing function.

Long-term anti-corrosion

Cathodic protection + barrier protection dual protection, salt spray resistance can reach more than 5000h, easily achieving long-term corrosion protection for more than 25 years;

Strong adhesion

The developed fusion agent technology solves the adhesion problem of high zinc powder content (dry film zinc content of more than 96%). A 4% mass fraction of fusion agent can firmly bond 24 times its own weight of zinc powder and combine the zinc powder with the substrate, with an adhesion of up to 5-10MPa.

Good matching

It can be used as a single layer, or as a two-layer or three-layer system with sealer, topcoat, zinc-aluminum coating, etc., to meet customers' needs for long-term protection and beautiful decoration.

The weld coating does not crack or fall off

It solves the industry pain point that cold galvanizing compound coatings are prone to cracking and falling off at welds, and the construction quality is guaranteed.

Easy construction

Single component, can be rolled, brushed, air sprayed, airless sprayed, does not sink to the bottom, does not clog the gun or pump, easy to apply.

High cost performance

Compared with hot-dip galvanizing and hot-spray zinc, it is environmentally friendly, low-cost, and easy to maintain; compared with epoxy zinc-rich, the maintenance and re-coating interval is long, and the anti-corrosion cost of the steel structure over the entire life cycle is low.